| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | Anywhere in India |

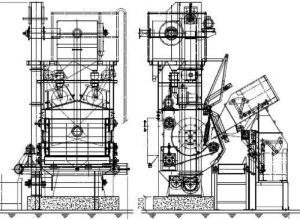

The blasting Wheel which is the heart of any shot blasting / peening machine has been so designed to generate a very high abrasive flow rate for any given HP. The number of wear parts within the wheel are as low as seven, as a result the spare part consumption & inventory are very low and this brings down the operational cost.

The wheels are available in four sizes :

- 250 Dia, 300 Dia, 400 Dia & 500 Dia. With 4, 6 & 8 blades configuration for different applications.

- The insertion and removal of blades are very simple & there are fewer number of steps involved as under thereby taking the least time to replace.

- Remove the top cover of the wheel housing & the top liner.

- Unscrew the bolt.

- Remove the blades.

- Insert blades and tighten the bolts.

- Place the top liner & close housing cover.

Details :

- CFC wheels are single sided wheels and are comparatively much lower in weight than a double sided wheel. Being a single sided wheel, the efficiency of these wheels are higher than a double sided wheel.

- CFC wheels are reversible i.e., the same wheel can be used for clockwise operation as well as for anti-clockwise operation by reversing the bare wheel.

- The bearings are heavy duty non greased type and require less maintenance.

- The wheel replacement is also very simple. No need of removal of complete wheel liners, only blade, impellor, control cage and top liner are to be removed. Thus the wheel replacement does not take more than 60 minutes under any circumstances.